miami lot house

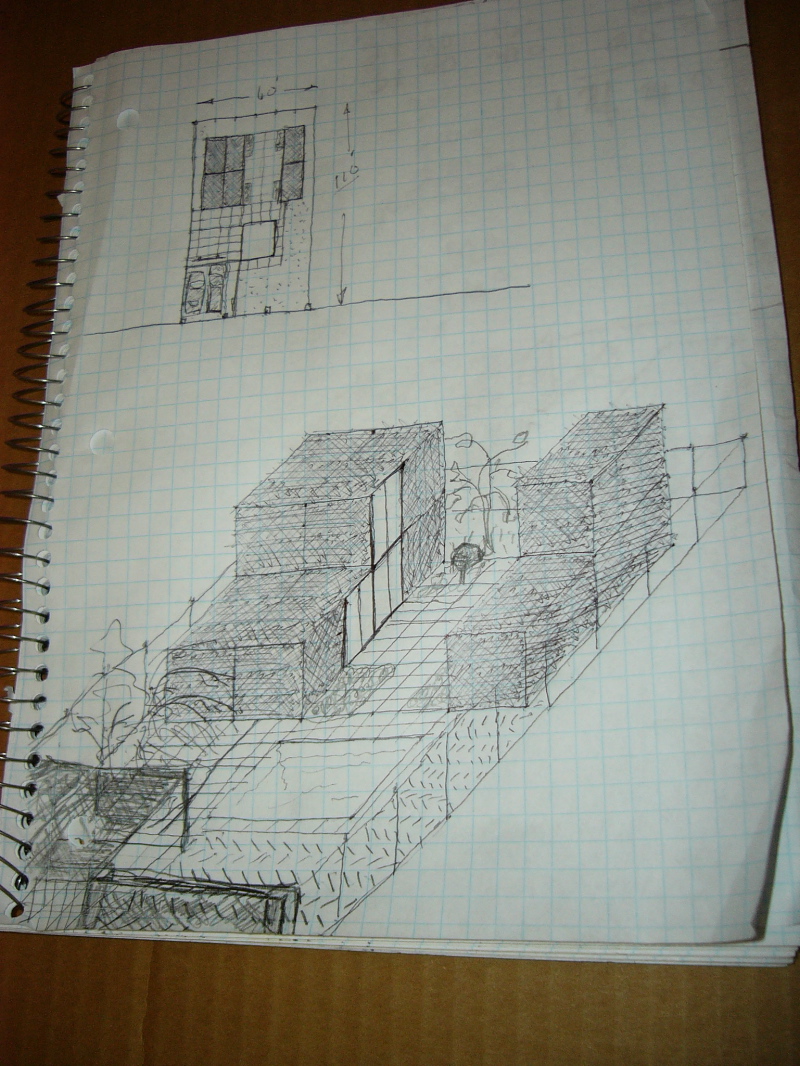

sketch for container house group on 110'x60' south florida (sub)urban lot. 8' chain link fence surrounds perimeter. cinder block front wall with iron gate. carport for two vehicles. 16' x16' pool. 48" x 48" concrete pavers for path and patio.

3 x 40' containers topped by 3 x 20' containers. total sf 1540 not including decks and patio. living quarters on left with internal spiral steel stairs access to 2nd floor. building on right has 1st floor gallery and external spiral steel stair (not visable) access to studio on second floor. galler/studi building has same sliding door/window configuration (not visible in drawing) as maine house. note gas grill on patio. grass lawn by pool. container heights 8' scale in drawing would be 9.5' in actual build.

A bit off topic but a friend of mine described working on a house, the skeleton of which was made of prefab interlocking hollow styrofoam blocks, kind of like large legos. The center of each block had a plastic stud running through it. Once the blocks were in place concrete was poured, filling the insides ot the blocks and creating a very well insulated concrete structure with studs 16" on center ready for drywall.

there are lots of advancements in the whole building process. im watching a house-reno/barn-conversion project on TOH. they are using a pre-engineered foundation that showed up at the building site on a flat bed. that means they use less concrete because they can engineer empty pockets, like using an I-beam instead of a solid chunk of steel. they use stress skin (osb-styro-osb) sandwiches for external walls that are really cool and are now showing up all over the place. they have the windows, doors, plumbing holes and electrical raceways pre-cut too. i dont know exactly the process your friends referring too but lots of new technology starts regional and works its way across the country.

Right, I think the process my friend worked with also saved on materials. And moving styrofoam blocks uses considerably less manpower and energy than concrete or brick with the concrete being poured in later by just a couple of workers.

Nice plan BTW

"...concrete being poured in later by just a couple of workers."

or robots.

|

- bill 1-17-2005 5:15 pm

- bill 1-17-2005 5:39 pm [add a comment]

sketch for container house group on 110'x60' south florida (sub)urban lot. 8' chain link fence surrounds perimeter. cinder block front wall with iron gate. carport for two vehicles. 16' x16' pool. 48" x 48" concrete pavers for path and patio. 3 x 40' containers topped by 3 x 20' containers. total sf 1540 not including decks and patio. living quarters on left with internal spiral steel stairs access to 2nd floor. building on right has 1st floor gallery and external spiral steel stair (not visable) access to studio on second floor. galler/studi building has same sliding door/window configuration (not visible in drawing) as maine house. note gas grill on patio. grass lawn by pool. container heights 8' scale in drawing would be 9.5' in actual build.

- bill 1-17-2005 5:48 pm [add a comment]

A bit off topic but a friend of mine described working on a house, the skeleton of which was made of prefab interlocking hollow styrofoam blocks, kind of like large legos. The center of each block had a plastic stud running through it. Once the blocks were in place concrete was poured, filling the insides ot the blocks and creating a very well insulated concrete structure with studs 16" on center ready for drywall.

- steve 1-18-2005 3:32 pm [add a comment]

there are lots of advancements in the whole building process. im watching a house-reno/barn-conversion project on TOH. they are using a pre-engineered foundation that showed up at the building site on a flat bed. that means they use less concrete because they can engineer empty pockets, like using an I-beam instead of a solid chunk of steel. they use stress skin (osb-styro-osb) sandwiches for external walls that are really cool and are now showing up all over the place. they have the windows, doors, plumbing holes and electrical raceways pre-cut too. i dont know exactly the process your friends referring too but lots of new technology starts regional and works its way across the country.

- bill 1-18-2005 10:10 pm [add a comment]

Right, I think the process my friend worked with also saved on materials. And moving styrofoam blocks uses considerably less manpower and energy than concrete or brick with the concrete being poured in later by just a couple of workers.

- steve 1-19-2005 1:21 am [add a comment]

Nice plan BTW

- steve 1-19-2005 1:23 am [add a comment]

"...concrete being poured in later by just a couple of workers."

or robots.

- tom moody 1-19-2005 2:54 am [add a comment]